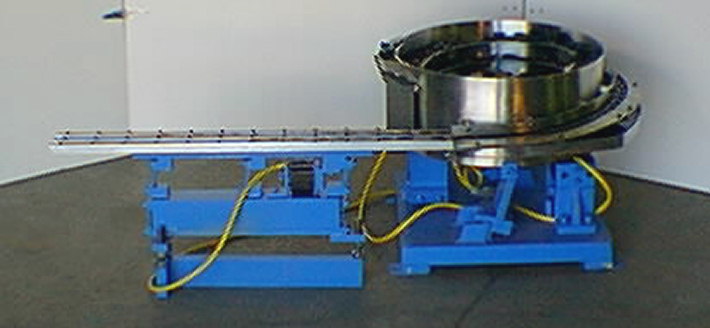

Vibratory Inline Feeders/Tracks

The basic concept of a vibratory inline feeder is to take the oriented parts from the discharge of the feeder bowl to the infeed port of the "host" machine, while maintaining the parts orientation. The tracks can be either single or multiple lane, and also provide accumulation and back-pressure on these accumulated parts for a more positive load of the oriented parts into the receptacle of the host machine.

- Our Vibratory Inline Feeders range in size form 4" in length to as long as 96" in length.

- Vibratory Inline Feeders are offered in both pharmaceutical and industrial grade finishes.

- Vibratory Inline Feeders are offered in either SST, Plated CRS, anodized aluminum, or plastic.

- High level sensors in the track(s) automatically control the output of the oriented parts from the feeder bowl to maintain the correct level of parts in the track itself.

- There are two styles of vibratory inline feeders that M & S offers.

- The standard inlines have a single variable speed control and this control is included.

- Another style of inline that is available self-monitors its vibration amplitude and automatically adjusts for changes in load conditions, voltage fluctuations, etc. to provide a very stable, consistent output.

- M & S Automated Feeding designs and fabricates all our vibratory inline tracks for the part handling characteristics required.